Exceptional pressure-bearing capacity

Engineered for high-pressure environments, suitable for deep and HPHT wells, ensuring operational stability.

A cementing head is a cementing device installed at the top of the casing during cementing operations, connecting the casing to surface manifolds. The cementing head enables operations such as circulation, spacer fluid injection, cement slurry injection, plug release, and spacer fluid displacement, serving as the central hub for surface manifold and wellhead operations during cementing. We provide a full range of cementing heads for drill pipe and casing applications. They are designed and manufactured with a modular approach, offering efficient solutions for both conventional casing string cementing and special cementing operations.

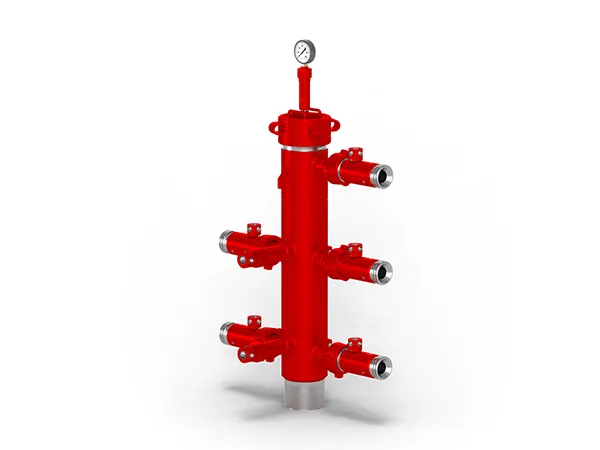

Single Plug Cement Head

A single plug cement head is designed to accommodates the upper plug during cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. The quick-connect coupling design ensures more convenient and reliable connections, and API standard threads or special thread connections can be provided. The product is also equipped with a plug drop indicator for easy operation monitoring.

It can couple with one plug, and make the drilling fluid fill into drill pipe in turn and quickly, simplify cementing operation and prevent cement pollution.

Double Plug Cement Head

A double plug cement head is designed to accommodate two-stage plug cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. The quick-connect coupling design ensures more convenient and reliable connections, and API standard threads or special thread connections can be machined as required. It is also equipped with a plug drop indicator for easy operation monitoring. It can be used for both conventional double plug cementing and continuous two-stage cementing operation.

Top-Drive Cement Head

A top-drive cement head is designed to accommodate single-stage or two-stage plug cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. The product is fitted a heavy-duty bearing capable of transmitting high rotational torque, and its built-in maintenance-free lubrication system ensures excellent performance under high temperature and high pressure conditions. It is primarily used for casing rotation cementing operations.

The top drive cement head allows the continuous and independent rotation, stroking (lifting) and high flow cementing simultaneously.

Clamp Type Cement Head

A clamp type cement head designed to accommodates the upper plug during cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. The quick-connect coupling design allows for a broader range of connections, making it more convenient and reliable to adapt to casings of the same size with different thread types. The product is also equipped with a plug drop indicator for easy operational monitoring.

The main feature is that the clamp type quick joint cement head is connected to the pipe through the clamp type quick joint device on the clamp type quick joint cement head to connect the casing to the casing to achieve well cementing. It can be used in cementing operations of some special button casings.

Rotating Cement Head

The rotating cement head is designed for single-stage or two-stage plug cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. This product is fitted with a heavy-duty bearing and a maintenance-free lubrication system, ensuring excellent performance under high temperature and high pressure conditions.

Rotating Cement Head System (RCH) executes the customer’s reciprocating and rotating cementing process while conditioning the well during the cement job. Designed for longevity, the rotating cement head features a no-leak swivel design that allows for continuous rotation over extended periods of time, resulting in a better cement job.

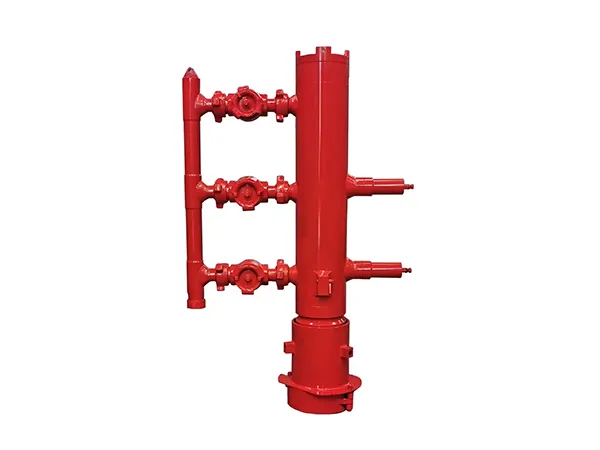

Double Plug Drill Pipe Cement Head

A double plug drill pipe cement head enables circulation, spacer fluid injection, cement slurry injection, plug release, and spacer fluid displacement operations. It is designed to accommodate two-stage cementing operations and is equipped with an independent plug valve circulating manifold. The complete range of specifications complies with SY/T 7084-2016 standard. The product is equipped with a lifting sub to meet operational requirements for moving the drill string during displacement operations. Additional functional expansions are available, such as adding a ball drop sub for liner operations or integrating a rotation system. It can be used for both conventional double plug cementing and two-stage cementing operation.

Exceptional pressure-bearing capacity

Engineered for high-pressure environments, suitable for deep and HPHT wells, ensuring operational stability.

Quick connection system

Modular structure supports rapid installation and removal, significantly reducing non-productive time.

Leak-proof sealing technology

Multiple sealing mechanisms effectively prevent cement slurry leakage, improving cementing quality.

Extensive compatibility

Compatible with mainstream casing sizes and tools to meet diverse operational needs.

Please download our PDF files for more detailed product specifications and dimensions.