Hydraulic-Mechanical Drilling Jar

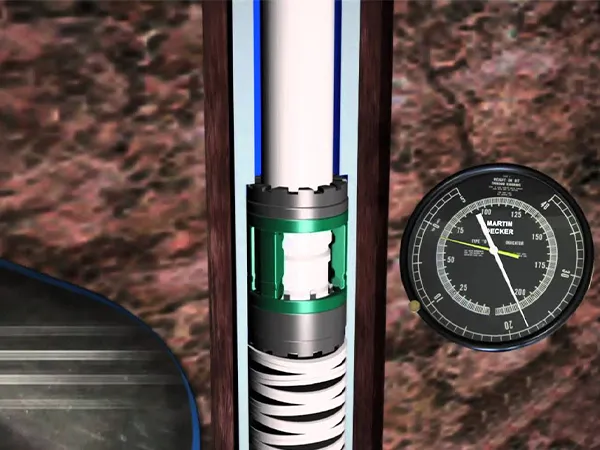

The hydraulic-mechanical drilling jar is an integrated up-and-down jarring tool that combines the advantages of both mechanical and hydraulic drilling jars, making it suitable for a wide range of drilling operations. This type of drilling jar incorporates the proven design features of Wenzel jar, utilizing hydraulic action for upward jarring and mechanical action for downward jarring, and it includes a locking mechanism to effectively prevent accidental jarring. Multiple jarring operations can be performed to free stuck pipe or obstructions, and quickly restore normal drilling operations.

The hydraulic energy storage mechanism utilizes premium imported copper alloy material for superior wear resistance and deformation prevention. The mechanical locking mechanism is manufactured using a specialized process to achieve low friction, stable linear locking force, and safe, reliable operation. The seal is sourced from internationally renowned suppliers, guaranteeing reliable quality. Together, these features enhance the overall safety, stability, and durability of the tool. It can be used in conventional wells, directional wells, and extended reach wells at operating temperatures ranging from 160 °C to 200 °C.

Overview

Overview Overview

Overview