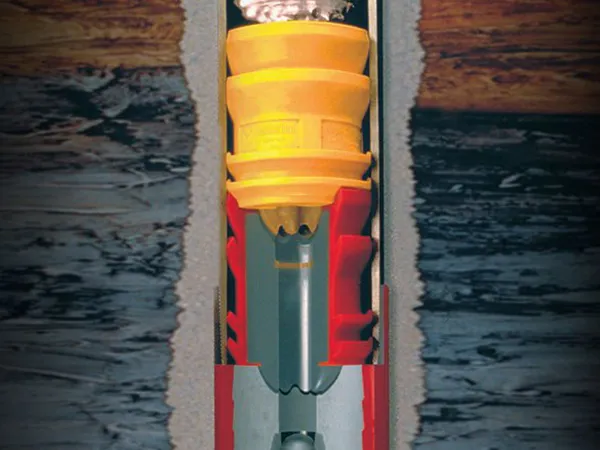

In most cases, cementing operations adopt the two-plug cementing technique, which includes a top plug and a bottom plug. Cementing plugs come in either standard or anti-rotation types.

Cementing plugs are pumped into the casing string through the cementing head. They isolate the cement slurry from the drilling fluid, wipe the casing wall clean, provide a bump-pressure indication of slurry placement, and prevent cement contamination. Selecting the right cementing plug is therefore critical to the success of the cementing operation.

In most cases, cementing operations adopt the two-plug cementing technique, which includes a top plug and a bottom plug. Cementing plugs come in either standard or anti-rotation types.

This technique is suitable for cementing operations on large-diameter conductor or surface casing strings (16" – 30"). In such cases, a specialized cementing plug – drill pipe self-locking plug – is required.

For complex well conditions or specific operational needs, an intermediate plug may be added. Specific applications include multi-stage cementing, prevention of cement slurry contamination, or special wellbore structures.

Other Cases

There are rare cases where only the top plug is used:

In addition, the cementing plug must be accurately sized to match the casing. Its body is made from nitrile rubber, offering excellent resistance to abrasion and high temperatures. The core is typically constructed from either aluminum alloy or polymer materials, depending on downhole conditions. Aluminum alloy cores are particularly well-suited for deep and ultra-deep well applications due to their superior strength and durability.