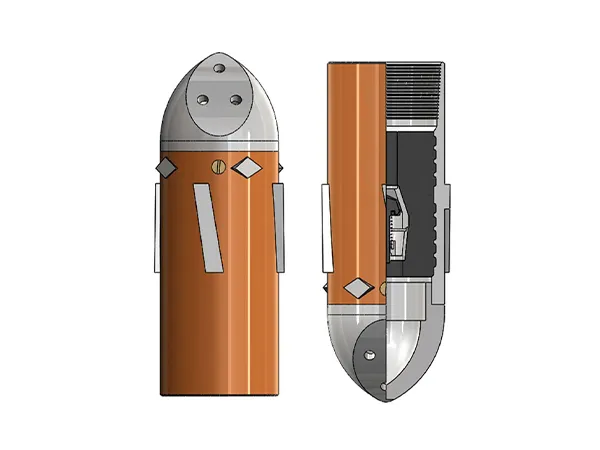

Guide float shoe

Float collars and float shoes are typically used as a set in casing operations. The float shoe is installed at the bottom of the casing string, serving to guide the casing smoothly through the wellbore while preventing mud backflow. Positioned one to two casing joints above the float shoe, the float collar functions to prevent cement slurry backflow, ensuring effective annular sealing.

Improper selection may lead to cementing failures, including seal failures, insufficient cement height, or casing running difficulties. Therefore, scientific matching based on well depth, pressure conditions, and well type is essential for optimal performance.

Guide float shoe

Reamer float shoe

Eccentric guide shoe

Free rotating eccentric nose guide shoe

Stab-in float shoe

Conventional float collar

Auto fill float collar

Differential fill-up float collar