Common downhole tools for underbalanced wells include check valves, air hammers and percussion drill bits, drill pipe, etc.

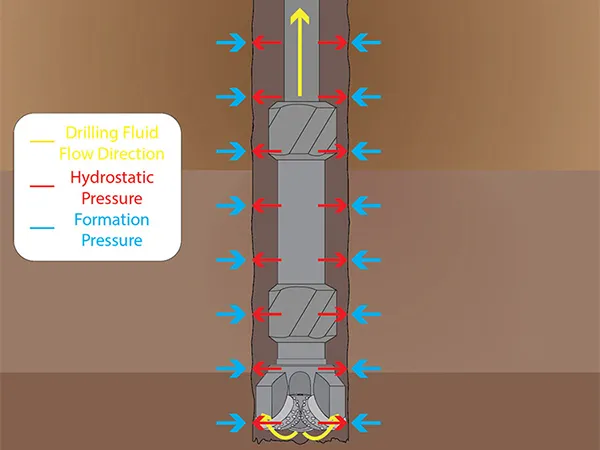

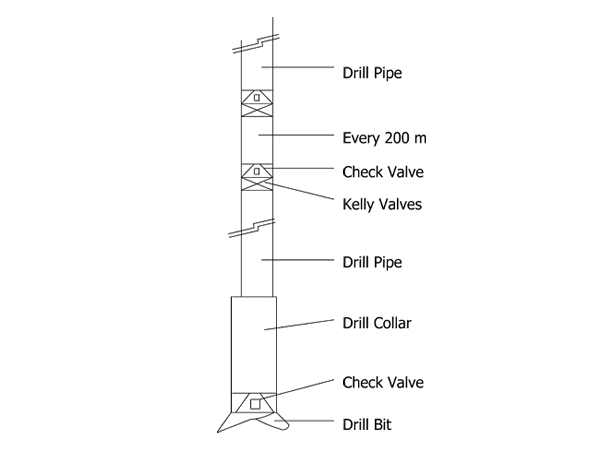

Since both the inside of the drill string and the annulus contain compressible two-phase fluids, when such fluids suddenly stop flowing, fluid inertia can create a 'vacuum' low-pressure effect within the pipeline, causing the backflow of the liquid column into the drill string. This backflow from the annulus into the drill string often causes the bit nozzles to become blocked, making it impossible to resume circulation after adding a single joint. To prevent this backflow, a check valve is installed above the drill bit (sometimes two are used in series for added safety). The check valve is typically used in conjunction with a Kelly valve, and then an additional set installed every 100 to 200 meters along the drill string, with the Kellyvalve below and the check valve above.

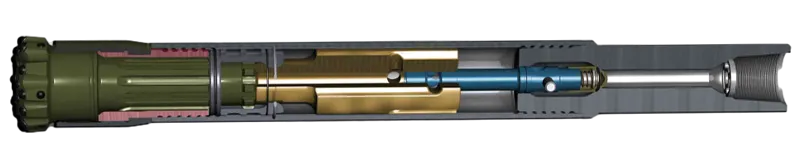

The air hammer and percussion drill bit are downhole tools specifically designed for air drilling. They rely on the conversion of the compression energy of high-pressure gas into the hammer’s impact energy to achieve rock breaking by impact, rather than by drill bit weight on bit. Air hammer drilling offers the advantages of high penetration rate, long service life, and better deviation control. The air hammer used in oilfield air drilling is a center exhaust, valveless, full-bore drilling air hammer. It mainly consists of a back sub, check valve, distribution seat, cylinder, outer casing, piston, tail pipe, retaining ring, and drill bit. Air hammer drill bits used in air drilling can be classified into integral and split types. In terms of the cutter material, they can be divided into tungsten carbide type and diamond type. According to the cutter edge shape, they can be categorized as blade type, button type, or mixed blade-button type. Currently, the air hammer drill bits applied in petroleum drilling mainly adopt a tungsten carbide button structure.

The drill pipe used for underbalanced drilling is a drill pipe with an 18° tapered shoulder, designed to facilitate the smooth passage through the rubber element of the wellhead rotating control device. It is also essential to smooth out burrs from tong marks after each single joint is connected, to ensure the extended service life of the rubber element. If a top drive system is used in conjunction, it can significantly reduce the number of single joint connections and extend the service life of the rubber element. Although some manuals specify that drill string connections for underbalanced drilling should use gas-tight threads (e.g. Grant Prideco XTM type), in actual operations, no significant issues have been observed when using conventional threads. In underbalanced drilling, especially air drilling, the torque on the drill pipe and the friction between the wellbore and the drill string are greater than in conventional overbalanced drilling, and drill string vibration is also more severe. Therefore, special attention should be paid to the proper design, use, and inspection of the drill string.