Basic Research on Float Collar and Float Shoe

Float collars and float shoes are critical tools in cementing operations, typically used as a matched set. The float collar and float shoe primarily serve to guide the casing string smoothly into the wellbore, adjust the buoyancy of the casing string during running, and utilize the back pressure valve to prevent cement slurry from flowing back into the casing. They also enable precise control of the cementing plug height within the casing during cementing, thereby ensuring cementing quality. The float collar additionally serves as a landing seat for the cementing plugs. The float collar and float shoe are installed on the casing string, with the float shoe positioned at the bottom of the casing string and the float collar located one to two joints above the float shoe, connected by threads.

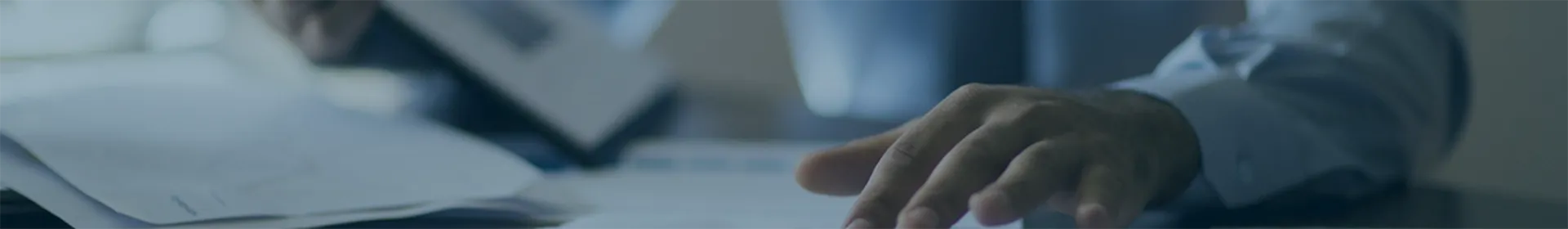

Basic Structure

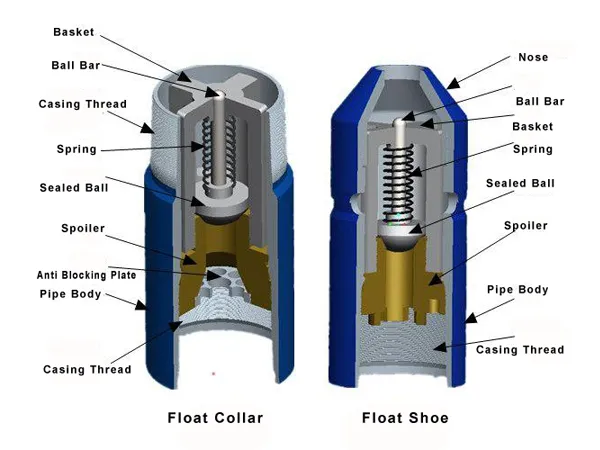

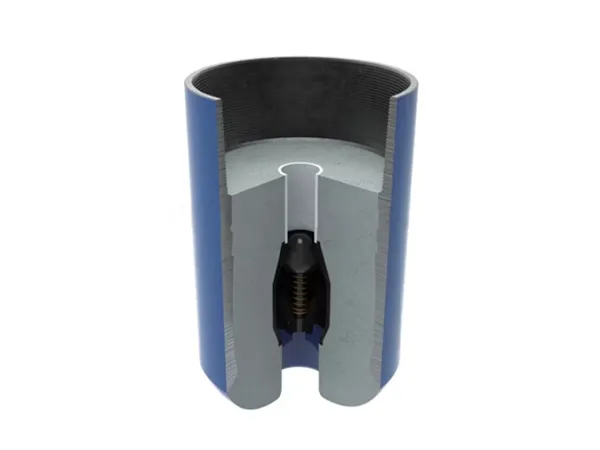

The float collar's structure is fundamentally identical to the float shoe, except its lower end features male threads for casing connection. The float shoe body is made of alloy structural steel, with the upper end connected to the casing and the lower end comprising a hemispherical cement or metal nose, which serves to guide the casing during running. A back pressure valve is installed internally to prevent cement slurry backflow and can be drilled out with a PDC bit. The upper and lower channels of the valve are open upon delivery from the factory. When the casing is initially run, there is no resistance from the well fluid to the float shoe. The pressure of the circulating mud pushes the valve head downward by a certain displacement, causing the three latches at the end of the valve stem to automatically disengage. After the pump stops, the valve is pressed tightly against the valve seat by the action of the spring, functioning as a check valve.

The materials for the float collar and float shoe are specified according to API 5L.

Overview

Overview Overview

Overview