Directional Well Drilling Technology

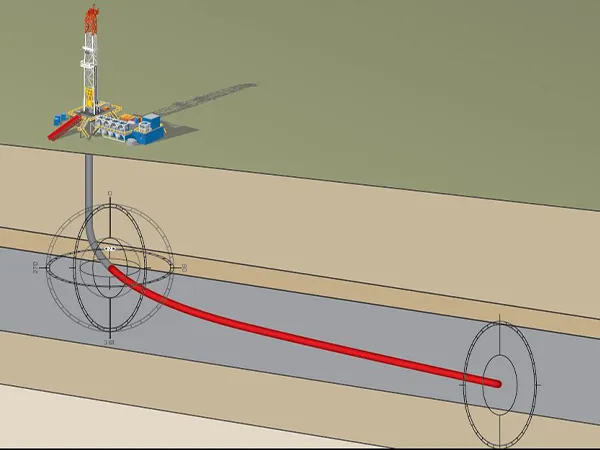

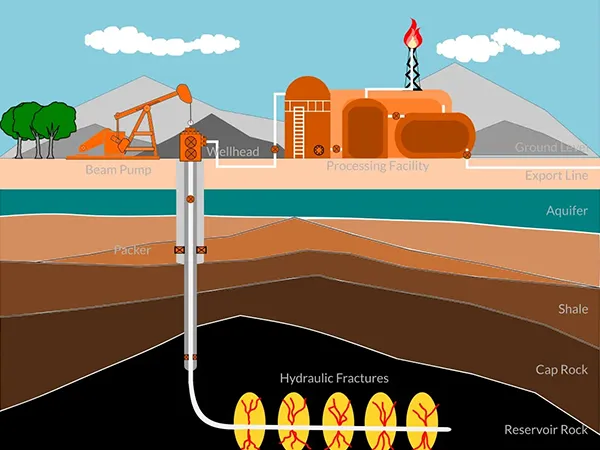

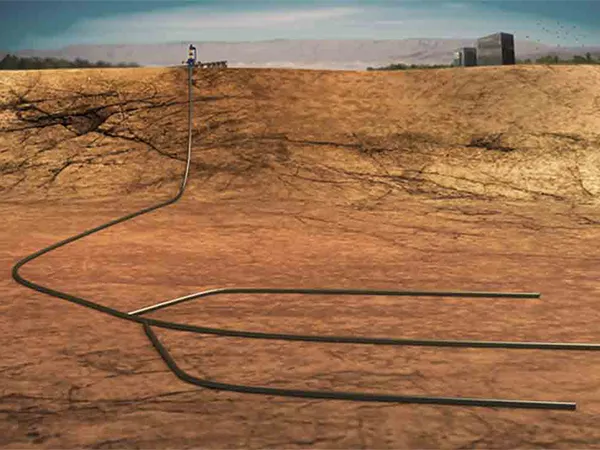

A directional well is a technical drilling term referring to a wellbore drilled along a pre-designed trajectory with controlled inclination and azimuth changes.

The primary objective of directional well design is to achieve the intended drilling purpose. This serves as the main basis and fundamental principle of directional well design. Designers must optimize the well profile, trajectory type, casing program, drilling fluid selection, and completion method based on specific drilling objectives to ensure safe, efficient, and high-quality drilling operations.

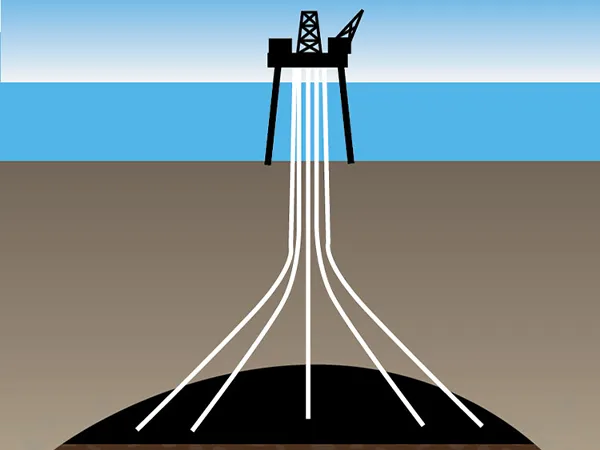

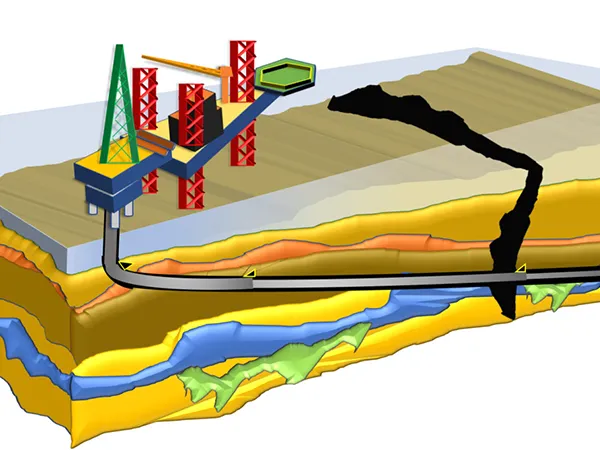

Applications include cluster drilling on artificial islands, directional wells drilling from onshore to offshore, fault-controlled trajectory drilling, drilling in areas where surface conditions (such as mountains or buildings) restrict access, subsurface trap exploitation, directional relief well engineering, deviation correction or sidetracking operations, multi-lateral target wells, and horizontal well development.

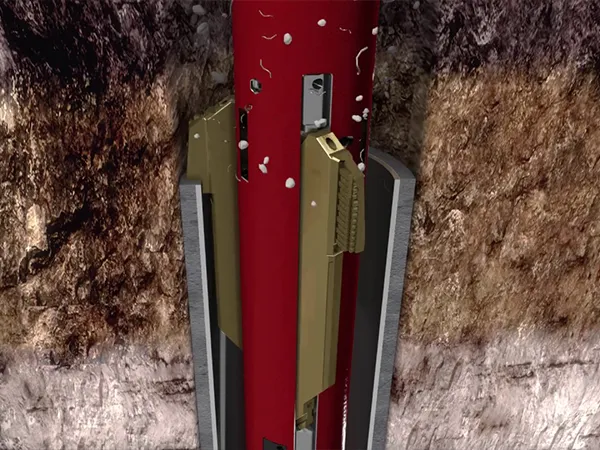

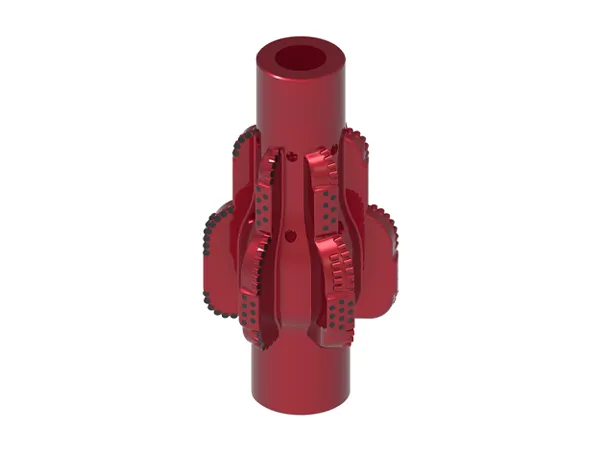

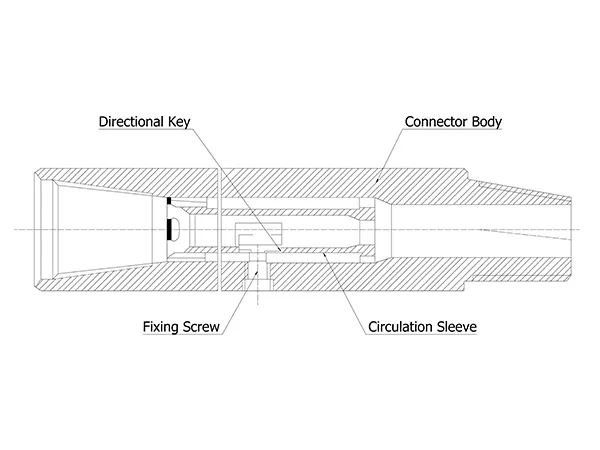

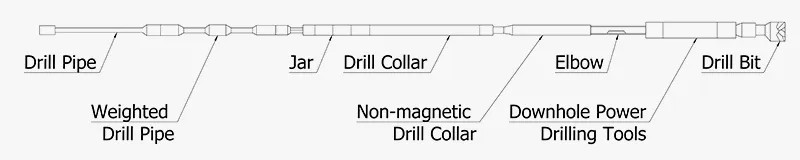

Drill string assemblies for directional wells are generally classified by their function into hold-angle assemblies, drop-angle assemblies, building-angle assemblies, micro-building assemblies, deflection tools, and steering systems. For each well section, appropriate BHA configurations and drilling parameters must be selected based on the planned well profile. This ensures the drilled hole follows the designed trajectory – the fundamental principle of directional well path control. When designing a directional well BHA, the principle of stiffness compatibility must be observed; that is, the stiffness of the entire drill string should gradually decrease and not increase, to avoid stiffness incompatibility that could prevent the drill string from being run in.

Overview

Overview Overview

Overview