High strength

It complies with API grades H40 to Q125, meeting the requirements of various well depths.

With the continuous development of the petroleum drilling industry, drilling environments have become increasingly complex and variable. Our technical team remains committed to the forefront of drilling operations, delivering superior oil casing solutions to global drilling contractors. In addition to API-standard oil casings, we offer a variety of non-API oil casings, including special steel grades and premium threaded connection products, to meet diverse customer needs. All oil casings undergo rigorous testing and validation to ensure compliance with international standards such as API 5CT and GOST, providing customers with reliable quality assurance.

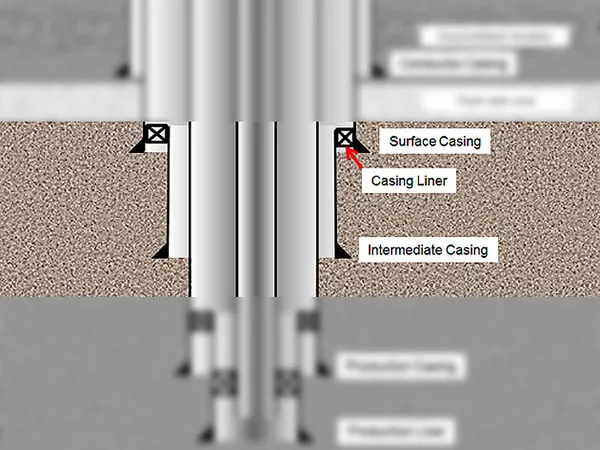

Conductor Casing

The conductor casing is the first string of pipe run in a well, typically set at depths ranging from 40 to 300 feet. Onshore, it is a short section of casing, usually around 60 feet (20 meters) in length. Its primary function is to isolate unconsolidated formations, water-bearing sands, and to prevent erosion from shallow sediments. It provides a fluid conduit from the drill bit to the surface and minimizes hole collapse issues as loose formations (like gravel) may fall into the wellbore, causing drilling problems.

Surface Casing

This is the second layer of casing, following the conductor casing, typically set at depths between 1,000 and 3,000 feet (300–900 meters).

The primary functions are to minimize shallow well losses; maintain wellbore integrity to prevent borehole collapse; cover weak formations during well control operations; support the blowout preventer (BOP) for well control, and protect shallow freshwater zones from contamination (therefore, surface casing is always anchored at the surface).

Intermediate Casing

Intermediate casing is a specialized type of casing used during drilling operations, positioned between the surface casing and the production casing. Some wells require multiple intermediate casing strings, while others may not need any. It is typically set in the transition zone from normal to abnormal pressure. The primary function is as follows: During drilling operations, numerous challenging formations may be encountered before reaching the production zone. These problematic formations require isolation with intermediate casing, such as lost circulation zones, unstable shale formations, squeezing salt layers, and abnormal pressure zones.

Production Casing

This is the final layer of casing in the oil and gas well casing program, running from the wellhead to below the penetrated oil and gas reservoir. Production casing is used to isolate the production zone and control formation pressure. Additionally, the production casing is designed to withstand injection pressures from operations such as fracturing, gas lift, or waterflood support.

Casing Liner

In a cased wellbore, a casing liner refers to a casing string that is cemented only across the open hole section without extending back to the wellhead. Instead, it is suspended from another casing string. During cementing operations, this method is specifically termed "liner cementing." The casing liner is typically run inside a shallower casing string, with an overlap between the two casing strings usually about 300–500 feet. The casing liner is generally cemented along its entire length. The casing liner is usually run in using drill pipe, which is retrieved after cementing.

High strength

It complies with API grades H40 to Q125, meeting the requirements of various well depths.

Precision threaded connections

Optimized thread geometry enhances tensile and compressive strength while reducing the risk of thread slippage.

Dimensional stability

Precision-controlled cold/hot rolling combined with real-time ultrasonic thickness monitoring ensures consistent quality.

Superior mechanical properties

Verified through Charpy impact tests, hardness testing, tensile tests, and other inspections to ensure compliance with API 5CT/ISO 11960 standards.

Please download our PDF files for more detailed product specifications and dimensions.