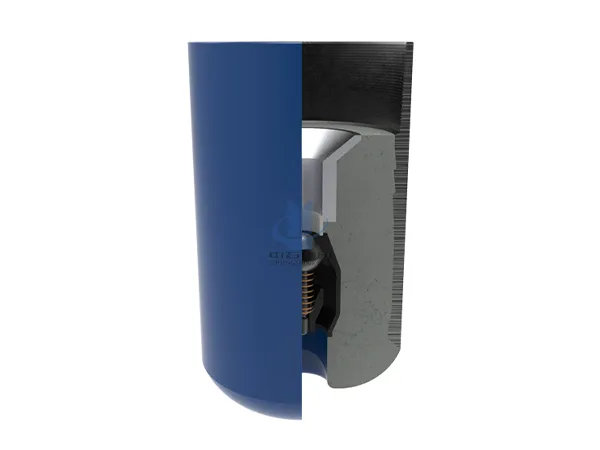

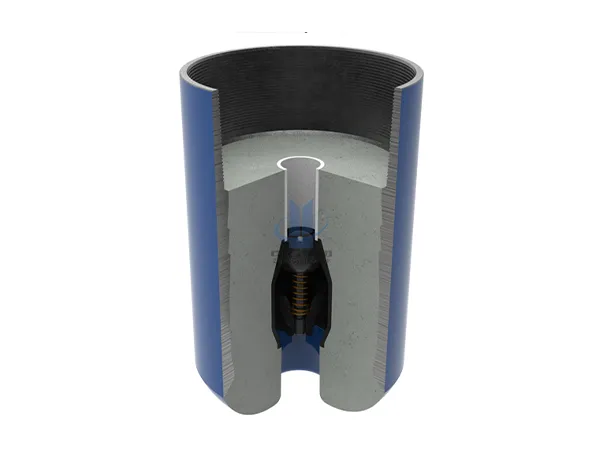

A reliable valve body structure ensures minimal resistance to cement slurry flow.

- Home

- Products

Products

Providing one-stop procurement services for global drilling contractors.

Overview

Overview - Solutions

Solutions

Delivering end-to-end solutions from drilling and cementing to well completion.

Overview

Overview - Resources

Resources

Providing comprehensive data support including technical articles, product specifications, etc.

- About

About Us

We always put people first and are committed to the path of sustainable development.

- Contact